How can we achieve it

Confidentiality of Drawings&Data Isolation: Sign a Non Disclosure Agreement (NDA) and manage the entire process of engineering and production permissions.

FAI pre planning: Upon project initiation, the first article (FAI) plan is created, with critical dimensional process cards pre positioned to the manufacturing process.

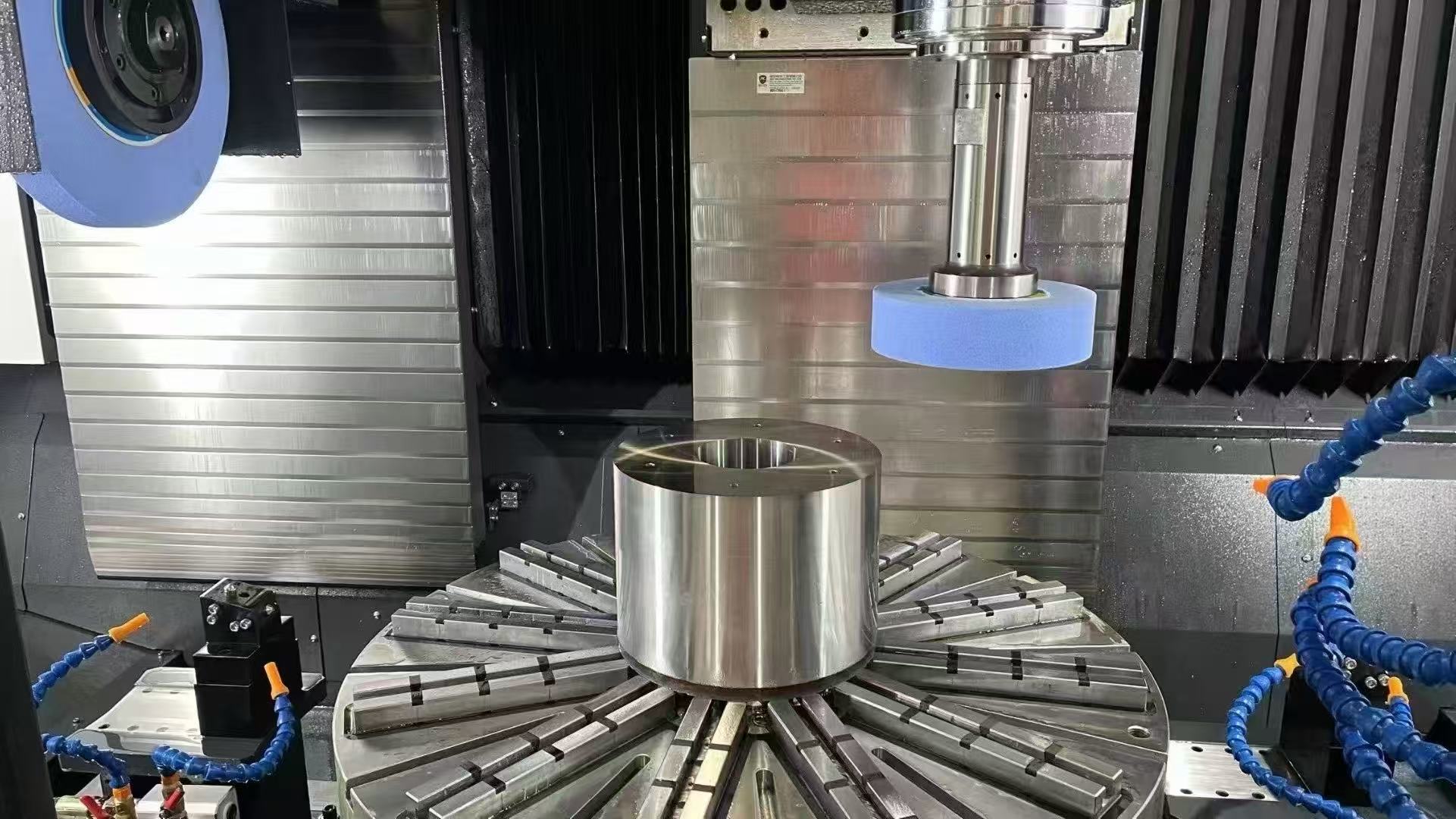

One time forming: turning milling composite+specialized fixture, reducing clamping errors and human fluctuations.

Constant temperature testing: CMM 100% rechecks critical dimensions under 22 ± 1 ℃ conditions.

Batch traceability: Material/heat treatment/surface/inspection one piece one code, retained for at least 3 years.

Deliverables and Metrics

Size/Capacity: Turning Ø 3 – Ø 1600/L ≤ 2200 mm; Milling Ø 1600 × 800 mm

Accuracy: Conventional ± 0.01 mm; Key position ± 0.005 mm; Grinding/grinding/grinding μ m level

Ø 1600 * 800mm, Ø 420 * 2200mm, 1000 * 1000 * 800 mm

Material: 45 steel D2、Q235、SKH-9、40Cr、ASP-23、HT150、P20、 Steel 35, 718, 65 Mn、NAK80、0Cr18Ni、s13、sus304、H1、Cr12、SKD6、DC53、8407、Cr12MOVFDAC、T10、T12、H136

Documents: FAI report, CMM shipment report, material/heat treatment/surface qualification certificate COC

Compliance: RoHS/REACH (on demand), operating according to ISO 9001 (certificate/switchable under construction)

Typical components: instrument frame, optical support bracket, sealing flange, positioning ring, assembly fixture/gauge base, etc.

Cycle: 5-15 working days for samples | 20-45 working days for mass production (based on drawings and schedules)

CTA: Upload drawings and provide manufacturability suggestions and quotations within 12 hours.