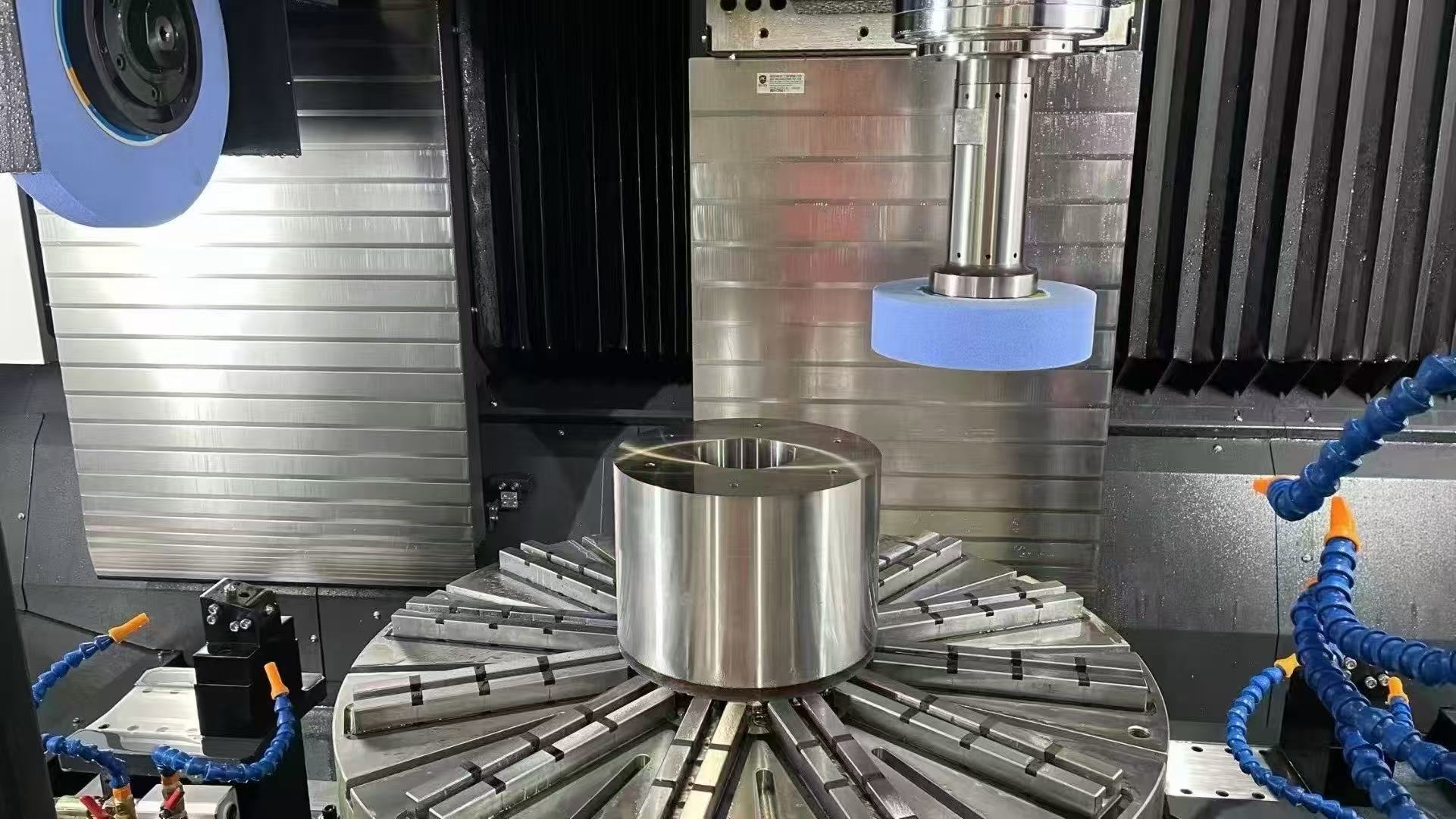

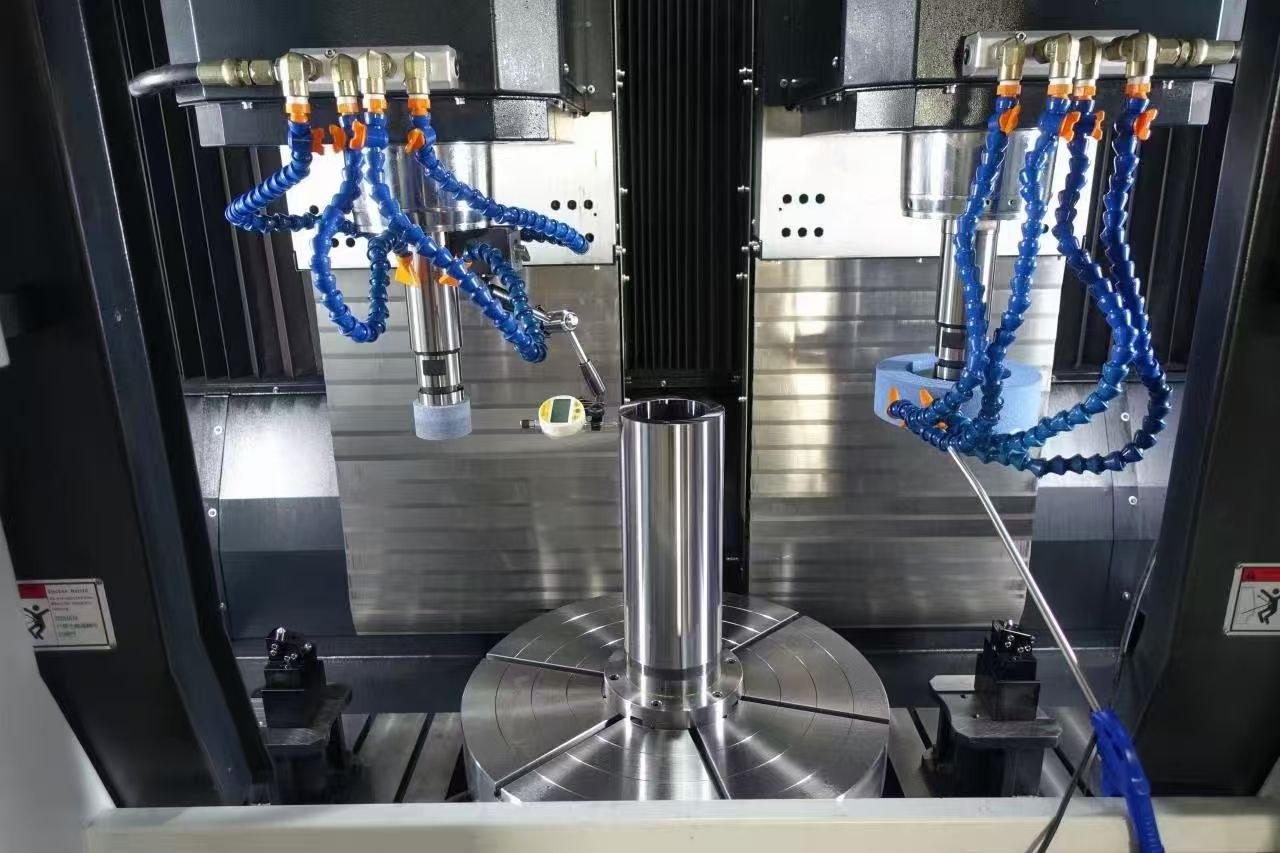

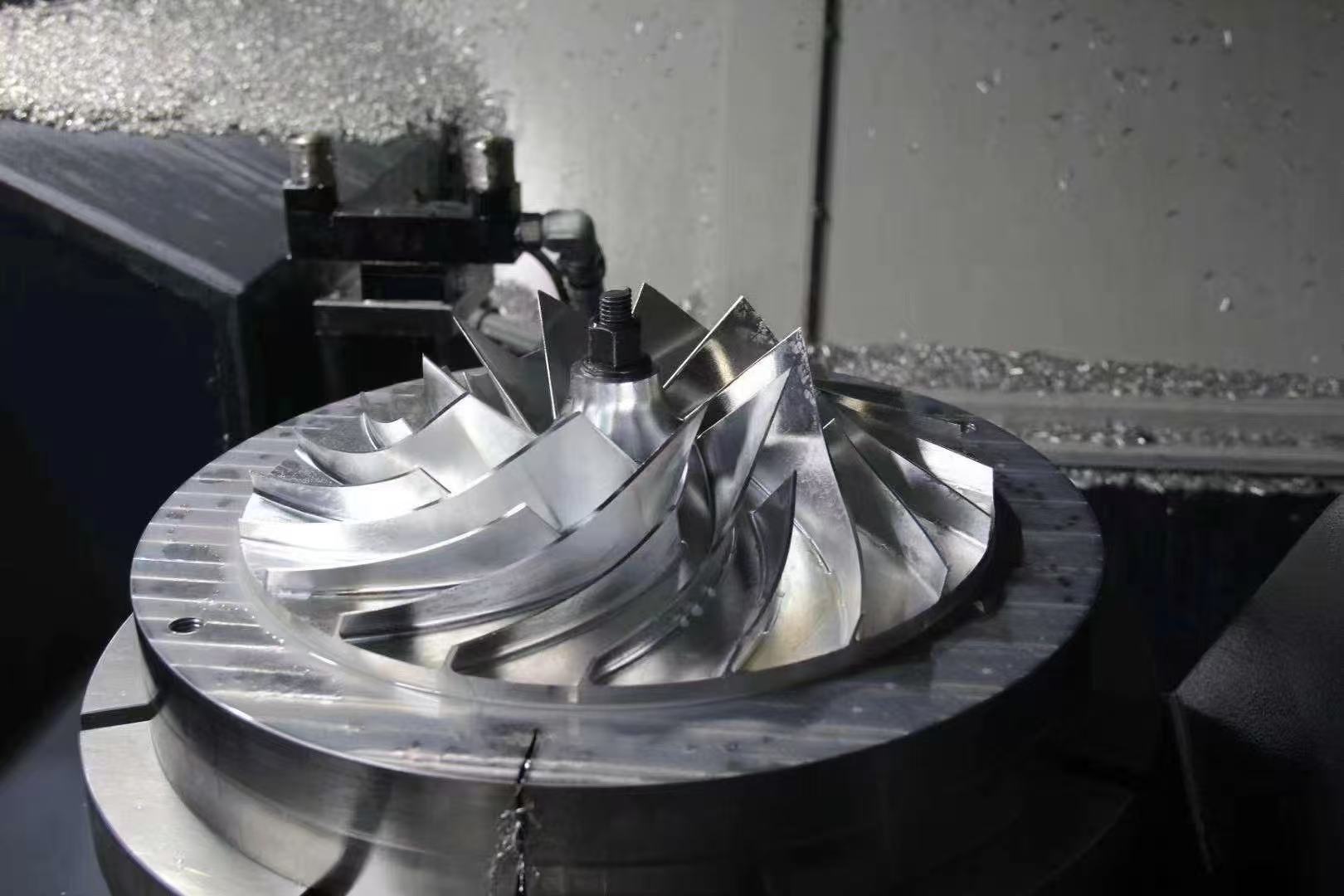

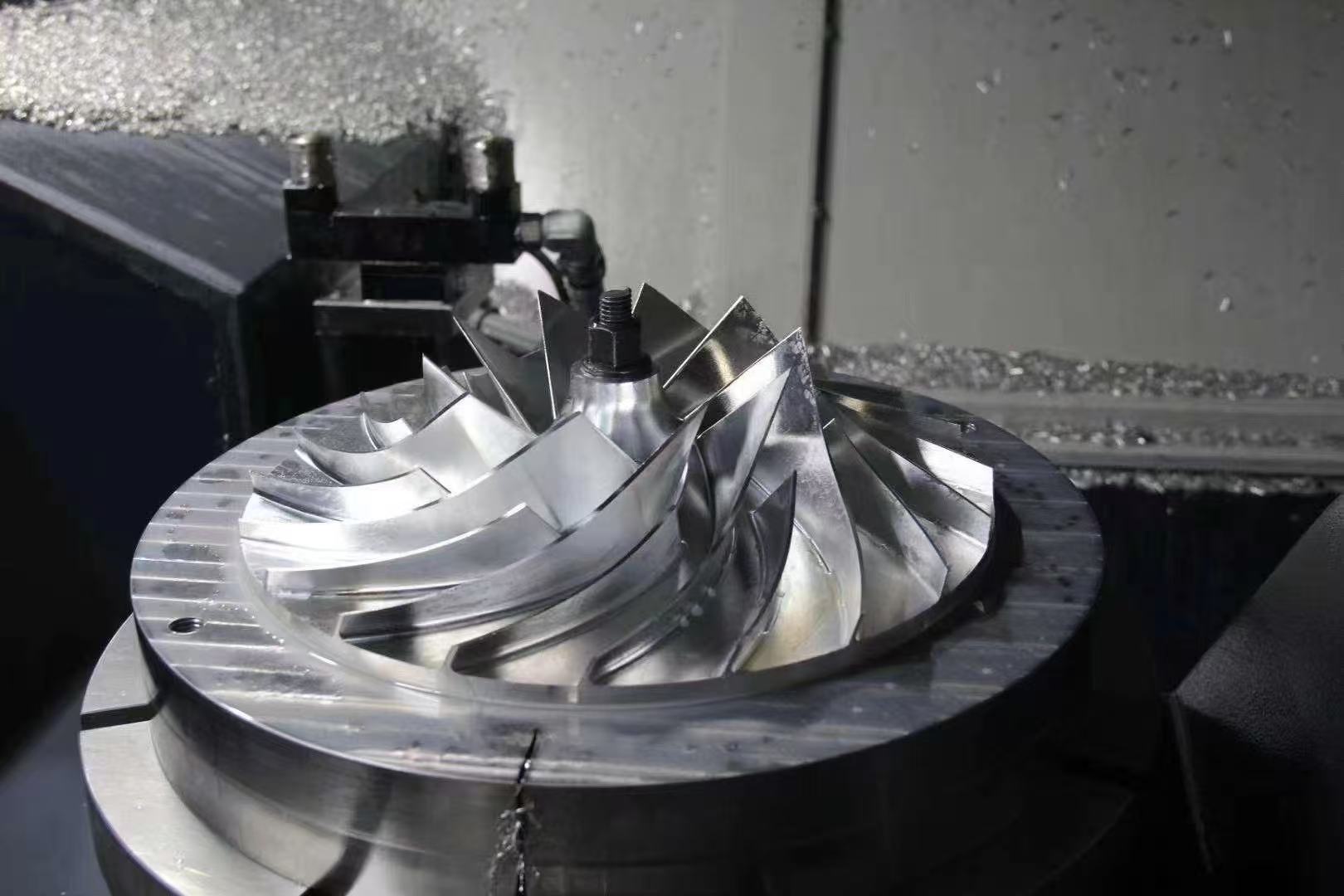

-Applicable scenarios : Polyhedra, oblique faces, irregular cavities, high consistency parts completed in one clamping (such as complex fixtures, robot joint seats, vortices/impellers, medical shells, optical mechanical structural components).

- Our Advantages

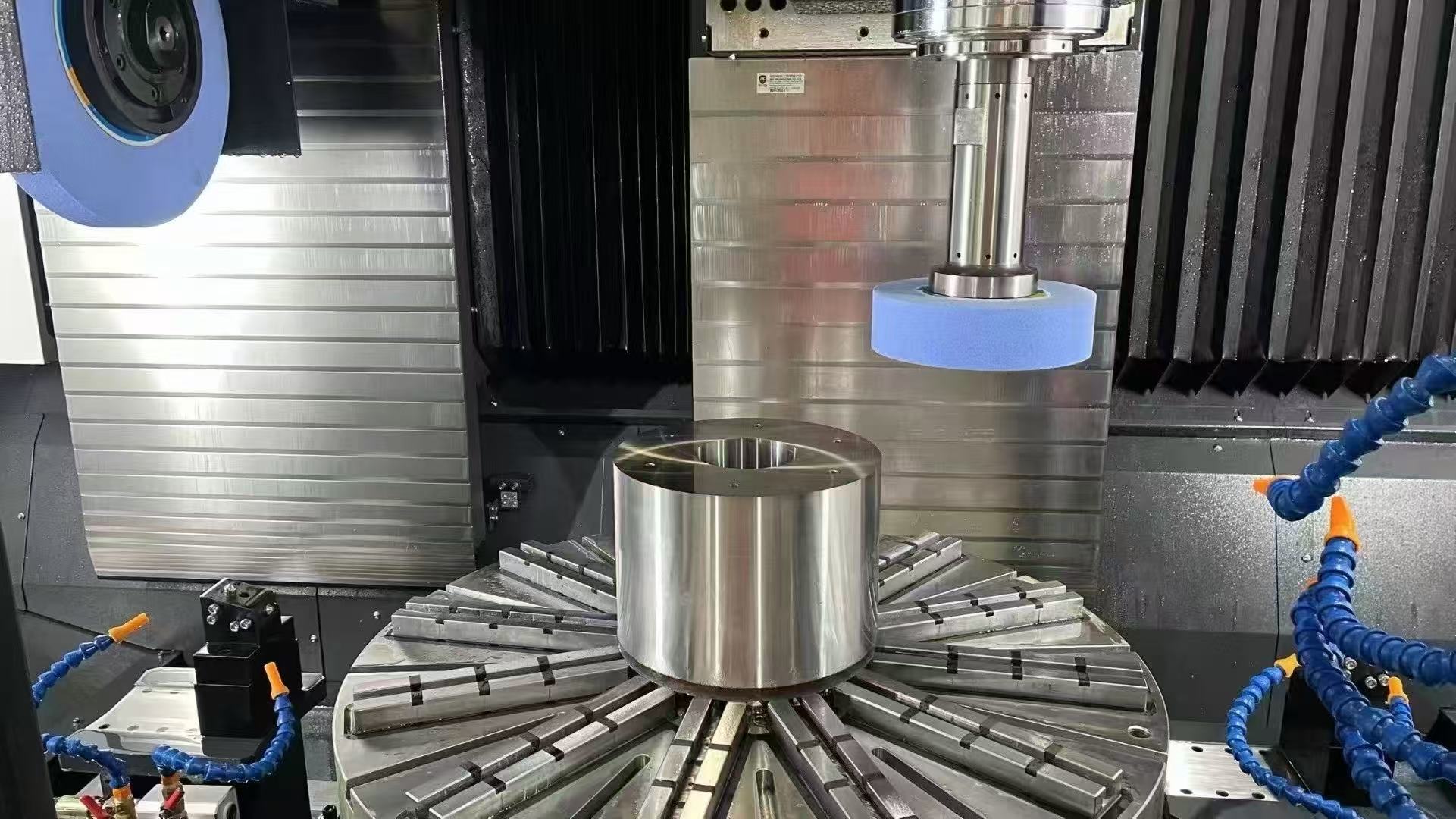

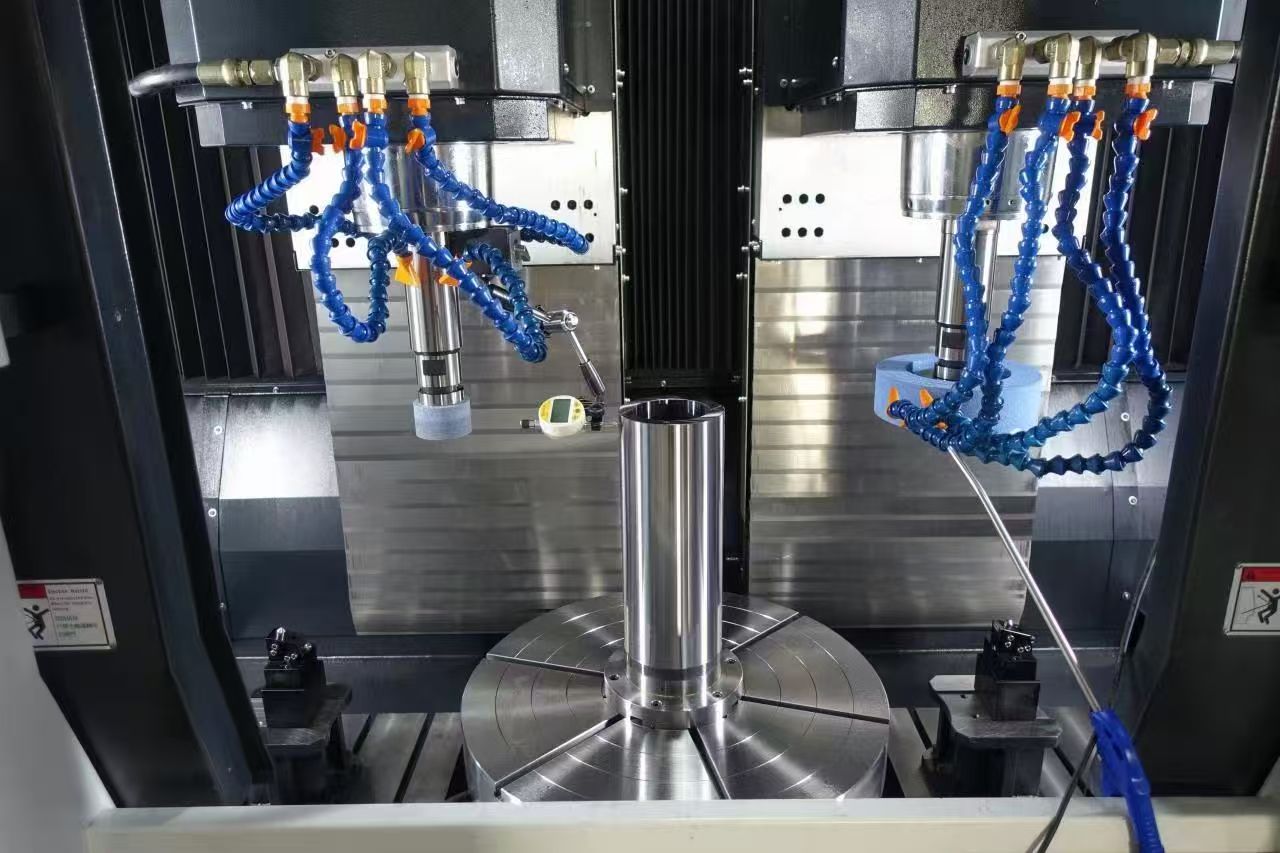

One clamping in place: Five sided linkage/positioning reduces secondary clamping errors, complex surfaces and hole positions complete at once 。

Excellent surface quality : Continuous cutting with fine knife marks; More stable angle control for curved surfaces, slanted holes, and stepped holes.

DFM support : Optimization of radius/cutting path/fixture, balancing accuracy and cost.

- Ability and Indicators (Typical)

Travel coverage 1000×1000×800 mm , Larger items can be divided/combined into tooling (up to a maximum of) 1600×800 mm Structural components within the scope.

Typical tolerances: ±0.01 mm ; Key positions to ±0.005 mm ; Matching grinding/matching research μ m level (depending on the material/structure).

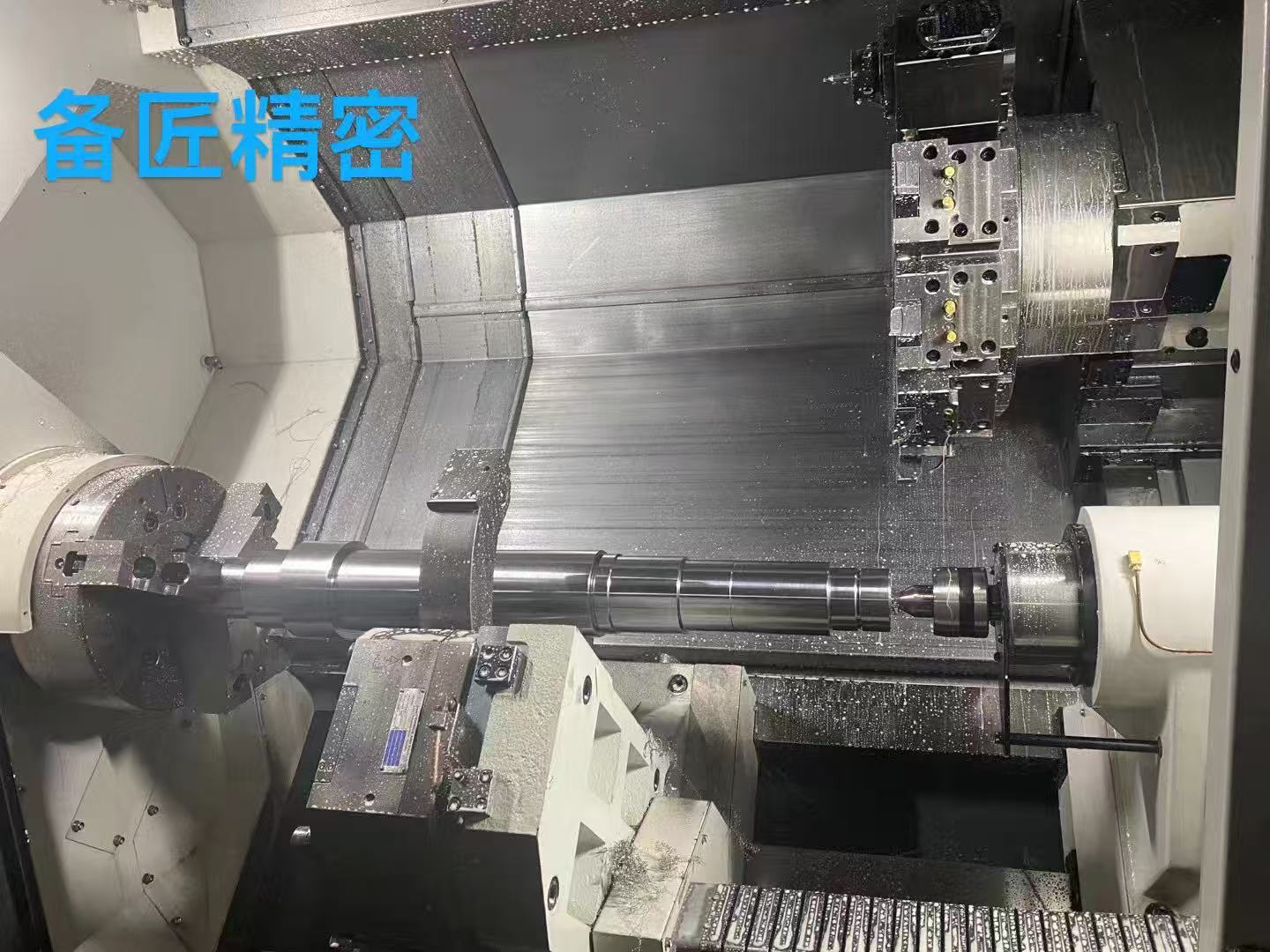

Materials: Aluminum 6061/7075, Stainless Steel 304/316/17-4PH, Alloy Steel 40Cr/42CrMo, Copper/Brass, Engineering Plastics POM/PEEK/PA, etc.

- Quality and Delivery

Constant temperature inspection room+CMM coordinate system; Three inspections: incoming materials, process, and shipment.

sample 7-10 days , batch 15-25 days ; Support NDA, VCI anti rust packaging, COC/material/heat treatment/surface reporting.

- Machinable Materials (excerpt)

Carbon/Alloy Steel: 45 #, 35 # Q235、40Cr、65Mn

Tool/Mold Steel: D2、Cr12/Cr12MoV、DC53、SKD6(A2)、P20、718、NAK80、8407(H13)、T10/T12、ASP-23、H136/S136

stainless steel: 0Cr18Ni(≈304)、SUS304、17-4PH Wait; Cast iron HT150 ; Copper/brass; POM/PEEK/PA and other engineering plastics

- post-processing

Heat treatment: Quenching and tempering, carburizing, nitriding, induction hardening, aging

Surface: Anodizing (natural color/hard coat/black), blackening, galvanizing/nickel plating, sandblasting/bead spraying QPQ wait

- Quality and documentation

Constant temperature testing room+ CMM three coordinate system ; Three inspections of incoming materials, process, and shipment

Can provide: Size/CMM report, material/heat treatment/surface report, COC certificate of conformity

Packing: VCI rust prevention+independent label+export wooden box ; support FOB/CIF/DAP/DDP, NDA confidentiality

- Quick Request for Quotation (RFQ) List

- 2D image (PDF/DWG)+3D model (STEP/IGS)

- Material, heat treatment, surface treatment standards

- Key Dimensions/Tolerances and Inspection Levels (FAI/CMM)

- Batch/rhythm and target delivery time; trade terms

- If it is an old part: sample photo/size/functional description (reverse mapping can be done)

-Key feature precision machining: ±0.001 mm (Constant temperature environment)

- Process chain: CNC rough machining → composite grinding → CMM review

- Supporting facilities: Zhongyuan 1380 Vertical Machining Center Used for efficient milling/positioning (room temperature ± 0.01 mm)